Business Challenge Key Features Business Benefits

SupplierSoft on-Demand Component Qualification/Production Part Approval Process (PPAP) solution provides companies a central repository for initiating, tracking and managing component qualification process. Ease-of-use, global performance and multi-lingual capabilities ensures rapid adoption across all geographies.

- Track component qualification requirements: For each component, the system enables tracking of configurable qualification requirements such as data sheets, Material declarations, Lab reports, Audits, SPC, FAI, OQA, FMEA, DFC, DFM, DFR, GRR and more.

- Track PPAP requirements: For each component, the system enables tracking of 18 PPAP requirements as outlined by AIAG: Design Records, Authorized Engineering Change Documents, Engineering Approval, DFMEA, Process Flow diagram, PFMEA, Control Plan, Measurement System Analysis Studies, Dimensional Results, Records of Material/Performance Tests, Initial Process Studies, Qualified Laboratory Documentation, Appearance Approval Report, Sample Production Parts, Master Sample, Checking Aids, Customer Specific Requirements and Part Submission Warrant (PSW)

- Configure PPAP Levels: Based upon component family, past supplier quality performance and the reason for PPAP, the PPAP levels (1-5) can be configured without any programming.

- Configure Phased PPAP: System supports phased PPAP requirements from OEMs such as Ford.

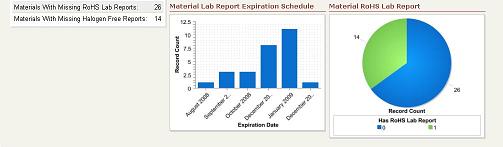

- Expiration based reminders: Multiple configurable expiration based reminders ensure that all the documents are collected on-time.

- Central qualification documents repository with search capabilities: PPAP documents for all components are kept centrally with the ability to search for specific document and keywords.

- E-mail based document exchange: Suppliers can e-mail documents to a central e-mail address (such as ppap@yourcompany.com ). The system automatically extracts documents from e-mails and attaches them to appropriate component and their qualification requirements.

- Integrated Environmental Compliance: The PPAP process is seamlessly integrated with the Environmental Compliance application, allowing for IMDS reporting.

- Integrated quality management: Component qualification is seamlessly integrated with corrective action and audit management applications.

- Configurable approval processes: Configurable multi-step and parallel approval processes enable approval of various requirements across functional departments such as component/supplier engineering, product/design engineering, procurement, quality, process engineering, environmental compliance and program management.

- Program/NPI Management: Program and NPI managers can track the status of all the components within a BOM and drill down to identity problem areas. Configurable program dashboards enable program managers to quickly check the health of the program at a glance.

- Configurable dashboards and reports: In addition to standard dashboards and reports that highlight the status of component qualification, configurable dashboards and reports enable business users to create personalized dashboards and reports with a few mouse clicks – all without IT involvement

- Contact management: Supplier contacts can be tracked along with expiration driven reminders.

- Outlook/Notes integration: Full integration with Outlook/Notes ensures that desk top is always in sync with the system. Entire communication history can be searched through, providing visibility into past interactions.

- Ease of use: A Web 2.0 user interface eases user adoption.

- Global performance: The system has superb performance across all geographies for global users.

- Multi-lingual: The system is enabled for translation in any language and can be easily translated into any language, improving user adoption.